What's Going on With my 1968 Ford Country Sedan?

After months of languishing, my wagon project is starting to build some steam.

Hi everyone! This week, we are taking a break from talking about other people’s cars to discuss the piece of junk I have been working on. That of course is my former daily driver, a 1968 Ford Country Sedan station wagon. It is an incredibly well preserved example and it is without a doubt the most gorgeously patinated and rust-free classic car I have ever owned. According to the VIN, it was built on April 19th, 1968 at the Los Angeles Ford assembly plant and was optioned in Seafoam Green with a tan interior. Most importantly, it rolled off the factory floor with a little red badge on the side which reads "390" in big bold letters. This indicates that under the hood lies an almighty 390 FE big block.

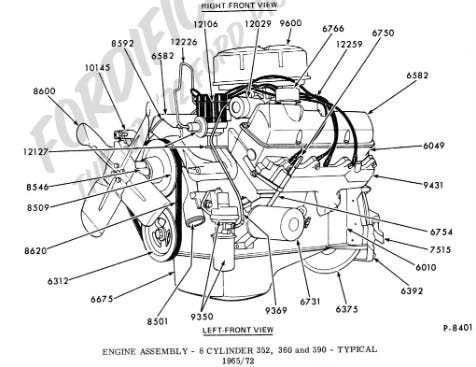

The term "big block" generally refers to the engine design capable of supporting the highest displacement in an automaker’s lineup. They do not share engine architecture with their smaller counterparts and they are generally intended for high performance and heavy duty applications. The Ford FE big block is one of the most robust and successful V8 designs of its era. Ford's Le Mans winning GT40s were fitted with FEs, as were their NASCAR and NHRA entries. Because this engine was designed in the “win on Sunday sell on Monday” era of the auto industry, Ford had the audacity to use this same Le Mans winning engine architecture in performance oriented passenger cars, heavy duty trucks, busses, boats, and even industrial pumps.

While the versatility of the Ford FE design can not be overstated, an engine is only as reliable as the person who maintains it and the 390 FE in my wagon did not receive the care and feeding it deserved. It was in fact a greasy, sludgy mess that was concurrently experiencing every major gasket failure and losing water through a crack in the block(!).

Let’s talk about that big one first. The block had cracked at the bottom of the passenger side water jacket, which is a coolant passage between the cylinders and the outer wall of the engine casting. This generally happens when someone puts water in their radiator (which freezes at 32 degrees Fahrenheit) instead of coolant (which freezes at -35 degrees Fahrenheit) and forgets to change it before winter. My working theory is that the Californians who brought my wagon to New Mexico never changed the water out for coolant and split the block open during their first winter in Santa Fe. Sometime after that, a shade-tree mechanic attempted to patch the crack with a clumsy smearing of JB Weld composite. By the time I purchased the wagon the crack was leaking slowly but steadily, as were the head gaskets, front and rear main seals, distributor gasket, valve covers, oil pan, and water pump. It takes a concerted effort (and some talent) to be this mechanically negligent.

Despite an entire generation of deferred maintenance, that greasy power-plant ran like a sewing machine during its tenure as my daily driver. It made 60lbs of oil pressure, started easy in any weather, and did not overheat in traffic on hot days. Under most circumstances I would elect to let sleeping dogs lie, but this car has grown on me in the past few years and I want to be able to trust it to do more than 20 mile round-trip commutes. With long-term automotive commitment in the picture for the first time in my entire history of car ownership, I knew the only way forward was a ground-up engine rebuild.

It was hard to work up the courage to break the seal on this perfectly operating mill. The day I started tearing down the engine, it still fired up quickly, ran smoothly, and made great oil pressure. I found it extremely difficult to come home from that final drive knowing that was the last time it would be driven in a completely original state, and knowing that it would be months before it moved under its own power again. Despite my hesitation, I am grateful that I started the rebuild when I did. Only upon tearing the engine down did I come to learn that my engine was an absolute time-bomb. Every single bore was scored, three pistons had cracked rings, the oil pan had about an inch of sludge at the bottom of it, and the oil pickup was half clogged with cork from crumbling gaskets. Sure, it ran smooth, but this thing probably should have bought the farm in the early 90s.

That was February, so let’s fast forward to today. As of this writing, it is early June. The original engine has been torn to pieces and the worthwhile bits have been saved (crank, rods, ancillary components and that’s about it). The bare replacement block I purchased (thanks rancher Joe!) last October is back from the local machine shop. It has been inspected and cleaned and bored and honed and all of the fancy skilled machine-work has been completed. Since the only major engine components I have saved are the crank and rods, I have the opportunity to build this new engine exactly as I would like. What does that mean?

That means that it’s going to be a total hot rod. This engine rebuild is just stage one of a multi-stage sportwagonification project that I will be undertaking with this car. I will get into the plan for my transmission, suspension, brakes, and interior in a later post, but here is what the engine will be getting. I will be fitting high compression forged pistons, ported cylinder heads with upgraded valve springs and rocker arms, an aggressive (but street oriented) camshaft, and an original Ford four barrel intake.

When all is said and done, it will have compression in the mid 9s and should have a meaty power band in the middle of the RPM range. With all of my required engine rebuild parts delivered and my block prepped, all that lies ahead is assembly. I have never built an engine from scratch before, let alone a hot rod engine, so just about anything could go wrong. If I fail to break-in the camshaft properly, the engine will abrade itself to death with metal shavings. If I torque a connecting rod improperly, it will exit my engine through the side of the block. If everything goes to plan, there will be celebratory burnouts and the purchase of a manual transmission. Regardless of what happens in the coming months, you’ll be sure to hear about it here.

Have a great week!

Oh am I excited for a burnout day at the drag strip. I’m thinking of dashboard trophies to make for when the wagon is complete!

Mauricio, I know nothing about cars but love this story and actually understand a little. I wondered how the car came into your possession.

Gary Smith

Concord Mass friend of your mother